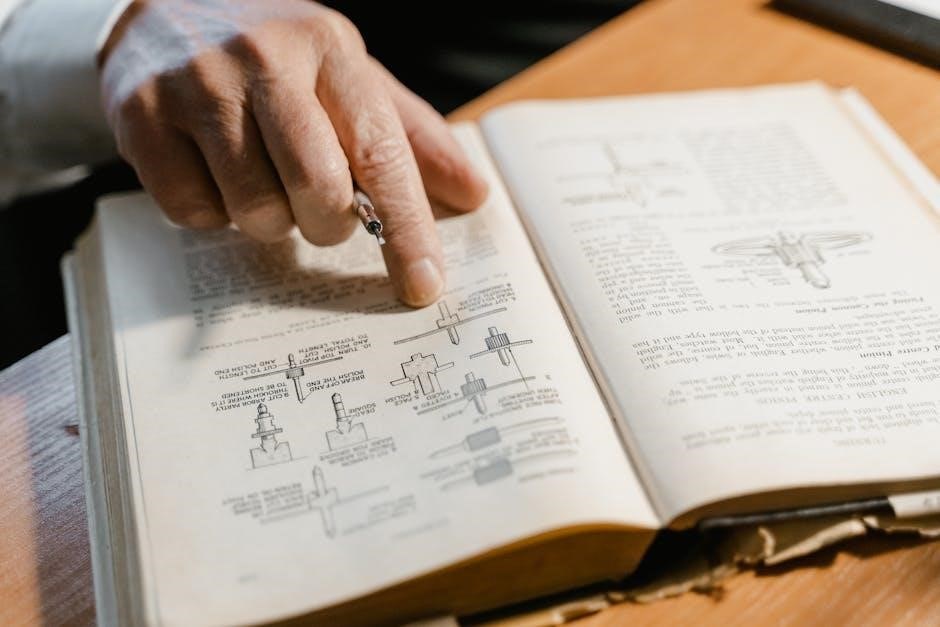

manual boost controller diagram

A manual boost controller is a device used to regulate boost pressure in turbocharged engines, offering precise control over performance. Diagrams and guides provide visual instructions for installation and operation, ensuring optimal engine efficiency and power delivery.

1.1 What is a Manual Boost Controller?

A manual boost controller is a mechanical device used to regulate boost pressure in turbocharged engines. It allows drivers to adjust the pressure delivered to the engine, optimizing performance. The controller operates by bleeding pressure from the wastegate actuator, enabling precise control over turbocharger output. Diagrams often illustrate its components, including the valve, spring, and hose connections, which work together to manage boost levels. This setup provides a straightforward, cost-effective alternative to electronic systems, making it popular among enthusiasts for fine-tuning engine performance.

1.2 Importance of a Manual Boost Controller in Turbocharged Engines

A manual boost controller is crucial for maintaining optimal performance in turbocharged engines. It prevents overboosting, which can damage engine components, and ensures consistent power delivery. By regulating boost pressure, it enhances engine reliability and efficiency. Diagrams highlight its role in managing wastegate actuator pressure, allowing precise adjustments to suit driving conditions. This control is essential for balancing power output and engine safety, making it a vital upgrade for turbocharged vehicles.

Key Components of a Manual Boost Controller

The manual boost controller consists of a valve, spring, and hose connections. These components work together to regulate boost pressure, ensuring precise control over turbo performance.

2.1 The Valve and Its Function

The valve is a critical component of a manual boost controller, responsible for regulating boost pressure by bleeding excess air to the atmosphere. It works in conjunction with the wastegate actuator to control turbocharger pressure. The valve’s design allows for precise adjustment, enabling drivers to set desired boost levels. Proper functioning ensures optimal engine performance and prevents overboosting, which can damage the engine. The valve’s operation is supported by the spring, which helps maintain the set boost pressure.

2.2 Hose Connections and Fittings

Hose connections and fittings are essential for ensuring proper airflow and pressure regulation in a manual boost controller system. Silicone hoses are often used due to their heat resistance and durability. The hoses connect the controller to the wastegate actuator and the turbocharger’s pressure source. Proper routing and securing of these hoses are critical to avoid heat damage and leaks. The fittings must be tightly sealed to maintain boost pressure and ensure reliable performance. Incorrect connections can lead to overboosting or system malfunction.

2.3 The Role of the Spring in Boost Regulation

The spring in a manual boost controller plays a critical role in regulating boost pressure by creating tension against the wastegate actuator. This tension determines the pressure required to open the wastegate, which controls turbocharger boost levels. Adjusting the spring allows for fine-tuning of boost pressure, with increased tension resulting in higher boost levels. Proper spring adjustment is essential to achieve optimal performance while preventing overboosting, which can damage the engine. The spring’s design ensures precise and consistent boost regulation under varying driving conditions.

How a Manual Boost Controller Works

A manual boost controller regulates boost pressure by bleeding pressure from the wastegate actuator, allowing the turbocharger to generate increased boost levels. Diagrams illustrate this process.

3.1 Basic Principle of Boost Pressure Regulation

The manual boost controller operates by adjusting the pressure supplied to the wastegate actuator. By bleeding excess pressure, it prevents the wastegate from opening prematurely, allowing higher boost levels. Diagrams show how the controller integrates into the system, ensuring precise regulation. This mechanism enables drivers to fine-tune boost pressure according to performance needs, enhancing engine power without overboosting risks. Proper installation, as shown in diagrams, is crucial for optimal functionality and safety.

3.2 The Relationship Between the Controller and Wastegate Actuator

The manual boost controller directly regulates the pressure sent to the wastegate actuator, controlling its operation. By bleeding excess pressure, the controller prevents premature wastegate opening, allowing higher boost levels. This relationship is crucial for maintaining desired boost pressures and ensuring proper turbo functionality. Diagrams illustrate how the controller integrates with the wastegate actuator to achieve precise pressure regulation, optimizing engine performance while minimizing risks of overboosting.

Installation Guide for a Manual Boost Controller

Install the manual boost controller by connecting it to the wastegate actuator and routing the boost reference line. Refer to the manual boost controller diagram for proper connections and ensure all hoses are securely fitted to avoid leaks or system failure.

4.1 Pre-Installation Steps and Safety Precautions

Before installing a manual boost controller, ensure the engine is cool to avoid heat-related damage. Disconnect the battery to prevent accidental startups and ensure proper grounding. Locate the wastegate actuator and boost pressure ports on the turbocharger. Remove the factory boost control solenoid if equipped, but leave it connected to the ECU. Use high-quality silicone hoses for connections to prevent cracking. Always consult the manual boost controller diagram for correct routing and connections to avoid system failure or engine damage.

4.2 Connecting the Controller to the Wastegate Actuator

Connect the manual boost controller to the wastegate actuator using high-quality silicone hoses to ensure durability. Refer to the manual boost controller diagram for correct port identification. The wastegate actuator typically has two ports: one for pressure input and one for exhaust. Secure the connections tightly to avoid leaks. Ensure the arrow on the controller points toward the wastegate actuator for proper flow direction. Double-check the routing to prevent interference with moving components or heat sources. Incorrect connections may lead to overboosting or system malfunction.

4.3 Routing the Boost Reference Line

Route the boost reference line from the turbocharger’s pressure source to the manual boost controller. Use heat-resistant silicone hoses to prevent damage from high temperatures. Secure the line with cable ties to avoid abrasion. Refer to the manual boost controller diagram for the correct connection points. Ensure no kinks or blockages impair pressure sensing. Proper routing ensures accurate boost pressure regulation and prevents engine damage from overboosting. This step is critical for maintaining reliable turbo performance and control.

Diagrams and Visual Aids

Diagrams provide clear visual guidance for installing and configuring manual boost controllers, including internal and external wastegate setups. Refer to Perrin and Lindsey Racing diagrams for detailed connections and routing.

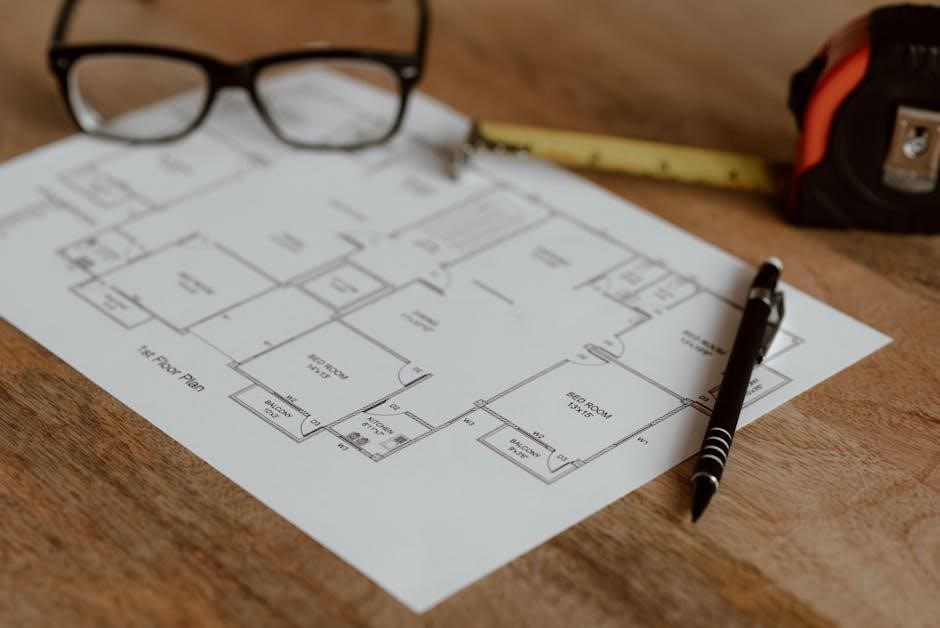

5.1 Internal Wastegate Setup Diagram

An internal wastegate setup diagram illustrates the integration of a manual boost controller with the turbocharger’s built-in wastegate. The controller is typically installed in the wastegate pressure line, with the arrow on the controller pointing toward the wastegate actuator. The diagram shows the connection of the boost reference line to the pressure source, ensuring proper routing and avoiding heat exposure. This setup allows precise regulation of boost pressure while maintaining system reliability and performance.

5.2 External Wastegate Setup Diagram

An external wastegate setup diagram shows the manual boost controller connected to a separate wastegate actuator, outside the turbocharger. The diagram illustrates the controller installed in the boost pressure line, with hoses routed from the pressure source to the wastegate. The external setup allows for higher boost levels and better control; Proper hose routing, away from heat sources like the turbine housing, is crucial. This configuration is ideal for high-performance applications, offering precise boost regulation and enhanced engine performance.

5.3 Hose Routing and Connections Diagram

The hose routing and connections diagram provides a clear visual guide for installing the manual boost controller. It shows the correct path for connecting the controller to the wastegate actuator, pressure source, and intake manifold. The diagram highlights key connections, such as the boost reference line and vacuum hoses, ensuring they are securely routed away from heat sources like the turbine housing. Proper routing prevents damage and maintains optimal boost control, while silicone hoses are recommended for durability and heat resistance. This setup ensures precise boost regulation and reliable engine performance.

Adjusting Boost Pressure

Adjusting boost pressure involves monitoring current levels and making precise modifications. Turn the controller dial to increase or decrease boost, ensuring adjustments align with engine performance needs. Always use a boost gauge to track changes and avoid overboosting, which can harm the engine. Start with small increments, test under load, and ensure all connections are secure to maintain optimal performance and safety.

6.1 Steps to Increase or Decrease Boost Levels

To adjust boost levels, start by locating the controller dial. Turn it clockwise to increase boost pressure or counterclockwise to decrease it. Use a boost gauge to monitor changes in real-time. Small adjustments are recommended to avoid overboosting. After each change, test the engine under load to ensure stability. Secure all hose connections to prevent leaks, which can affect accuracy. Always refer to the manual boost controller diagram for guidance on proper adjustment techniques. This ensures safe and effective tuning of your turbocharged engine.

6.2 Monitoring Boost Pressure During Adjustment

Monitoring boost pressure is crucial during adjustments to prevent overboosting. Use a high-quality boost gauge connected to the intake manifold for accurate readings. Observe the gauge while applying full throttle to ensure pressures remain within safe limits. If fluctuations occur, adjust the controller gradually and retest. Refer to the manual boost controller diagram for correct installation of the gauge and pressure lines. This ensures precise control and protects your engine from potential damage caused by excessive boost levels.

Safety Considerations and Precautions

Always follow installation guidelines to prevent engine damage. Risks include overboosting, which can harm turbo components. Proper controller setup and referencing diagrams ensure safe operation and reliability.

7.1 Risks of Overboosting and Engine Damage

Overboosting can lead to severe engine damage, including cracked pistons and turbocharger failure. Proper installation and adjustment of the manual boost controller are critical to avoid these risks. Referencing diagrams ensures correct setup, preventing excessive pressure buildup. Always monitor boost levels during operation to maintain safe limits and protect your engine from potential harm. Regular inspections of hoses and connections are essential to prevent leaks and system failure.

7.2 Proper Installation to Avoid System Failure

Correct installation of the manual boost controller is vital to prevent system failure. Use silicone hoses and ensure all connections are secure to avoid leaks. Refer to the manual boost controller diagram for proper routing of the boost reference line and wastegate actuator connections. Mount the controller in a cool, accessible location, away from heat sources. Follow manufacturer guidelines to ensure optimal performance and reliability, minimizing the risk of engine damage and maintaining system integrity. Regular inspections are recommended to uphold functionality.

Troubleshooting Common Issues

Common issues with manual boost controllers include boost pressure fluctuations and leaks. Check connections for tightness and inspect hoses for damage. Refer to the manual boost controller diagram for proper installation and routing. Ensure the wastegate actuator is functioning correctly and adjust the spring tension if necessary. Addressing these issues promptly prevents further complications and maintains optimal performance.

8.1 Diagnosing Boost Pressure Fluctuations

Boost pressure fluctuations can indicate issues with the manual boost controller or wastegate actuator. Start by checking for vacuum leaks in the system, as these can cause inconsistent pressure readings. Inspect the controller’s hose connections and fittings for tightness and damage. If the wastegate actuator is not functioning properly, it may fail to regulate pressure effectively. Refer to the manual boost controller diagram for proper installation and routing. Adjusting the spring tension or replacing worn components may resolve the issue. Monitoring boost levels during operation and comparing them to expected values can help pinpoint the root cause. Ensure all components are clean and free from debris, as contamination can disrupt normal operation. If fluctuations persist, consult the troubleshooting guide or seek professional assistance to avoid engine damage.

8.2 Resolving Leaks in the Boost Control System

Leaks in the boost control system can lead to inconsistent performance and reduced efficiency. Begin by inspecting all hose connections and fittings for tightness and damage. Replace any cracked or worn-out hoses with high-quality silicone alternatives. Ensure the manual boost controller is properly installed, referring to the diagram for correct routing. Check the wastegate actuator for proper sealing and operation. If leaks persist, inspect the boost pressure supply port and solenoid connections. Addressing leaks promptly prevents further system damage and maintains optimal boost regulation.

Advanced Tuning Techniques

Advanced tuning involves fine-tuning the manual boost controller for optimal performance, referencing detailed diagrams to ensure precise adjustments and maximize engine efficiency under various driving conditions.

9.1 Fine-Tuning the Controller for Optimal Performance

Fine-tuning a manual boost controller involves precise adjustments to the spring tension and valve operation, guided by diagrams to ensure the desired boost levels are consistently achieved. This process often requires monitoring boost pressure during various driving conditions and making incremental changes to optimize performance. Proper tuning prevents overboosting and enhances engine reliability, while detailed setup diagrams provide a clear visual reference for accurate modifications.

9.2 Using a Boost Controller with Other Performance Modifications

Integrating a manual boost controller with other performance upgrades, such as high-flow intake systems or aftermarket exhausts, enhances turbocharged engine performance. Diagrams illustrate how these components work together to maximize power delivery. Proper installation and tuning ensure compatibility, while monitoring boost levels prevents overboosting. Combining a manual controller with engine modifications requires careful setup to maintain balance and reliability, as outlined in detailed setup guides and visual aids.

A manual boost controller enhances engine performance by regulating boost pressure efficiently. Proper installation and adjustment are crucial for optimal power delivery and engine protection, ensuring safety and reliability.

10.1 Summary of Key Points

A manual boost controller is essential for optimizing turbocharged engine performance. It allows precise control over boost pressure, enhancing power delivery and efficiency. Proper installation, as shown in diagrams, ensures safety and reliability. Adjustments should be made cautiously to avoid overboosting, which can damage the engine. Regular monitoring and maintenance are crucial for sustained performance. Always refer to the manufacturer’s guidelines and visual aids for accurate setup and tuning.

10.2 Final Tips for Effective Use of a Manual Boost Controller

Always install the manual boost controller correctly, referencing diagrams for proper connections. Start with low boost levels and gradually increase, monitoring performance. Avoid overboosting to prevent engine damage. Regularly inspect hoses and fittings for leaks or wear. Adjust the spring tension carefully for precise control. Use a boost pressure gauge to ensure accurate readings. Finally, consult the manufacturer’s guide for specific tuning recommendations to maximize efficiency and safety.