Drive shaft manufacturing process pdf Bend of Islands

2018 SHAFT COLLECTION Fujikura Golf identify the failure cause and condition of the drive shaft. Then do the hardness test to know how hard the material that use in drive shaft. After that we can make an analysis and we try to solve the problem. 1.3 Objectives of Project Analyze the failure of drive shaft that used in Toyota SEG due to the hardness

AN OVERVIEW OF GEAR MANUFACTURING PROCESSES

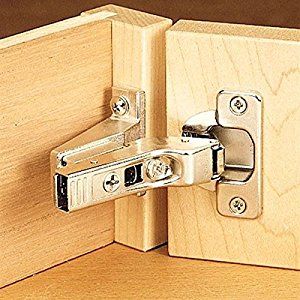

Propeller Shaft Manufacturing Pdf Download. Connection between a gearbox and drive shaft. Could someone add some picture on connection between a gearbox and drive shaft? —The preceding unsigned comment was added by Mnajib (talk • contribs) 20:31, August 21, 2007 (UTC). Driveshaft material and manufacturing process. What materials are used to make a driveshaft? What manufacturing, Download PDF Info Publication number US6698076B2 This invention relates to a method of fabricating a drive shaft to accommodate axial movement between a vehicle transmission and a drive axle. Typically, a driveline for a motor vehicle includes a shaft extending along an axis between a transmission and a differential of a drive axle. Each end of the shaft includes a yoke that forms one.

HGV Shafts & Components. We offer a repair service on all HGV Shafts & stock all components for reapir and modifaction so turn around time is usually within 24hours. No shaft is too big or too small we offer a full repair on Scania, Volvo, Mercedes, Man, Daf and many more. Drive shafts are used generally in power transmission applications e.g. automobiles, aerospace, pumping industries etc. Current study is deals with the study of automobile drive shafts. In automobiles drive shaft is connected with two ends by using universal joints to transmit power at angle. These shafts are experienced to twisting movement

Drive shaft Hub Differential gear Stabilizer Drive shaft Knuckle spindle Lower arm Untempered steel Case hardening steel Soft cold forged steel Spring steel Bearing steel [Automobile] 04 05 Automobiles made in Japan are well-known as being No.1 in the world in terms of quality and performance. MANUFACTURING PROCESS 103. MANUFACTURING PROCESS Each radial shaft seal is made for an application, which uses a particular fluid, runs at a pre-determined speed, has certain temperatures and pressures, and is in a spe- cific environment. Because of this the manu-facturing process of each type of seal may have some additional steps or modifications. In general the seal consists of three main

06/09/2017В В· ODM (Zhejiang ODM Transmission Technology Co., Ltd.) is a Sino-foreign joint venture enterprise with the capability of R&D, designing and manufacturing for C.V. Joints and Drive Shafts. However, there is another major source of forces imposed on a crankshaft, namely PistonAcceleration.The combined weight of the piston, ring package, wristpin, retainers, the connecting rod small end and a small amount of oil are being continuously accelerated from rest to very high velocity and back to rest twice each crankshaft revolution.

Drive shafts are used generally in power transmission applications e.g. automobiles, aerospace, pumping industries etc. Current study is deals with the study of automobile drive shafts. In automobiles drive shaft is connected with two ends by using universal joints to transmit power at angle. These shafts are experienced to twisting movement However, there is another major source of forces imposed on a crankshaft, namely PistonAcceleration.The combined weight of the piston, ring package, wristpin, retainers, the connecting rod small end and a small amount of oil are being continuously accelerated from rest to very high velocity and back to rest twice each crankshaft revolution.

Shaft manufacturing, materials and shaping 1. Shaft manufacturing, materials and shaping Course: Machine Elements 1 Student: Subkhiddin Mukhidinov ID: 47816 2. What is Shaft or Gear? • A shaft or gear is a wheel with teeth that meshes with the teeth of another shaft to transmit power on a continuous basis • Combining shafts of different Development of Additive Manufacturing 1 Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving

DRIVE SHAFT – DRIVE SHAFT SYSTEM DS–1 DS DRIVE SHAFT SYSTEM PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of the problem symptom. The potential causes of the symptoms are CV Shafts and Joints used in commercial and taxi operations - 3 months. Claims for replacement of parts will only be processed after inspection and acceptance by the Company and/or its supplier that product is defective in materials or workmanship.

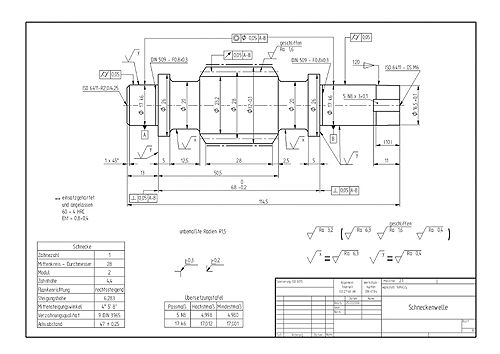

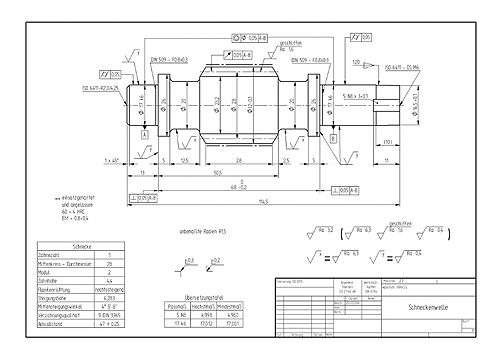

Figure 1-1 Drive train gear transmissions for heavy trucks. a) Scania GRS905R 12+2-speed gearbox with Scania Retarder b) Scania single drive axle (Illustrations from Scania CV AB). This thesis examines process planning and manufacturing of complete gear parts used … Optimization of a Process Chain for Gear shaft Manufacturing Fritz klocke, Markus Brumm, Bastian nau and Arne Stuckenberg Printed with permission of the copyright holder, the American Gear Manufacturers Association, 1001 N. Fairfax Street, Fifth Floor, Alexandria, VA 22314-1587. Statements presented in this paper are those of the author(s) and may not represent the position or opinion of the

Ganga Forgings is a well-known Yoke forgings manufacturers in India. With us, you get quality yoke pins, shafts, ball, and body. Our forged yoke manufacturing services are acclaimed worldwide and we provide to you high-quality industrial equipment and components. Necessity to use new materials, demanding functional requirements and miniaturization have led to evolution of modern manufacturing processes. Developments are taking place both in the conventional methods and unconventional methods of manufacture. High speed machining, hard machining, non conventional processes like beam, mechanical and chemical

Development of a High Torque Density, Flexible, Composite Driveshaft Duncan J. Lawrie President Lawrie Technology, Inc. Girard, Pennsylvania duncan@lawrietechnology.com Abstract An all-composite driveshaft incorporating integral flexible diaphragms is described. An approach was explored which obsoletes the split lines and associated fasteners required to attach metallic flex elements and 4. Manufacturing concepts and rationalisation within process planning L6 page 21 4.1 Planning complexity and new manufacturing concepts L6 page 21 4.2 Options for rationalisation in process planning L6 page 22 4.3 Methods for the rationalisation of operations scheduling L6 page 24 5.

AmTech International - manufacturing supplier of CNC machining parts, cold forge, hot forging, die casting, stamping, precision gear & shaft manufacturers. DRIVE SHAFT – DRIVE SHAFT SYSTEM DS–1 DS DRIVE SHAFT SYSTEM PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of the problem symptom. The potential causes of the symptoms are

Based on my research, a drive shaft, driving shaft or propeller shaft is a mechanical component for transmitting torque and rotation that usually used to connect other components of a drive train that cannot be connected directly because of distance or the … DRIVE SHAFT – DRIVE SHAFT SYSTEM DS–1 DS DRIVE SHAFT SYSTEM PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of the problem symptom. The potential causes of the symptoms are

Prop Shaft Manufacturing ACMC - YouTube. Necessity to use new materials, demanding functional requirements and miniaturization have led to evolution of modern manufacturing processes. Developments are taking place both in the conventional methods and unconventional methods of manufacture. High speed machining, hard machining, non conventional processes like beam, mechanical and chemical, Drive shafts are used generally in power transmission applications e.g. automobiles, aerospace, pumping industries etc. Current study is deals with the study of automobile drive shafts. In automobiles drive shaft is connected with two ends by using universal joints to transmit power at angle. These shafts are experienced to twisting movement.

Development of Additive Manufacturing Technology

China Shaft Shaft Manufacturers Suppliers Price Made. CV Shafts and Joints used in commercial and taxi operations - 3 months. Claims for replacement of parts will only be processed after inspection and acceptance by the Company and/or its supplier that product is defective in materials or workmanship., Drive shaft Hub Differential gear Stabilizer Drive shaft Knuckle spindle Lower arm Untempered steel Case hardening steel Soft cold forged steel Spring steel Bearing steel [Automobile] 04 05 Automobiles made in Japan are well-known as being No.1 in the world in terms of quality and performance..

Modern Manufacturing Processes A Review

FAILURE ANALYSIS OF DRIVESHAFT OF TOYOTA SEG. Precision Shaft Manufacturing. Forster Tool has been machining a variety of shafts and custom shafts for over 50 years. We have machined a variety of different custom shafts, from many different types of materials, ranging from titanium to plastic. https://en.m.wikipedia.org/wiki/Powertrain AmTech International - manufacturing supplier of CNC machining parts, cold forge, hot forging, die casting, stamping, precision gear & shaft manufacturers..

Based on my research, a drive shaft, driving shaft or propeller shaft is a mechanical component for transmitting torque and rotation that usually used to connect other components of a drive train that cannot be connected directly because of distance or the … 26/11/2015 · Licensed to YouTube by AdRev for Rights Holder, AdRev for a 3rd Party (on behalf of Abaco Music Library (5 Alarm Music - Abaco)); ASCAP, LatinAutor, AdRev …

China Shaft manufacturers - Select 2020 high quality Shaft products in best price from certified Chinese Bearing manufacturers, Gear Shaft suppliers, wholesalers and factory on Made-in-China.com DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT . A.Sridhar. 1, Dr. R. Mohan. 2, R.Vinoth Kumar. 3 1. PG Scholar Department – Product Design and Development, Senior Faculty Department of Mechanical Engineering, Sona College of Technology, Salem-636005, Tamil Nadu . 3. Mechanical Faculty in Knowledge Institute of Technology, Salem . ABSTRACT

Shaft manufacturing, materials and shaping 1. Shaft manufacturing, materials and shaping Course: Machine Elements 1 Student: Subkhiddin Mukhidinov ID: 47816 2. What is Shaft or Gear? • A shaft or gear is a wheel with teeth that meshes with the teeth of another shaft to transmit power on a continuous basis • Combining shafts of different 12/12/1995 · The invention proposes a process for manufacturing a transmission shaft made of a composite material comprising at least one step for producing an external layer comprising reinforcing fibers impregnated with a heat-curable resin, characterized in that a peripheral sheath made of a knitted article is installed over the external layer prior to the curing of the resin during the polymerization

Analysis of Drive Shaft 24 ANALYSIS OF DRIVE SHAFT 1BHIRUD PANKAJ PRAKASH, 2 the latest technology and various manufacturing methods has raised application range of these materials. Drive shafts are usually made of solid or hollow tube of steel or aluminum. Over than 70% of single or two-piece differentials are made of several piece propeller shaft that result in a rather heavy drive shaft How Shafts Are Made. The manufacture of golf shafts depends upon the type of material that is being used. Steel shafts are either pulled or rolled and welded. Graphite shafts are made with multiple layers of material wrapped around a mandrel. Composite shafts (combination of steel and carbon fiber) are made according to the design and

Propeller Shaft Manufacturing Pdf Download >>> shurll.com/aa8x5 Alibaba.com offers 212 drive shaft manufacturing process products. About 15% of these are machining. A wide variety of drive shaft manufacturing process options are available to you, such as free samples.

Development of Additive Manufacturing 1 Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving DRIVE SHAFT – DRIVE SHAFT SYSTEM DS–1 DS DRIVE SHAFT SYSTEM PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of the problem symptom. The potential causes of the symptoms are

Drive Shaft Manufacturing. As a small batch drive shaft manufacturer, we focus on quick response ordering with the potential for custom changes available to meet your production requirements. Our goal is to reduce your inventory, improve your cash flow, and … HGV Shafts & Components. We offer a repair service on all HGV Shafts & stock all components for reapir and modifaction so turn around time is usually within 24hours. No shaft is too big or too small we offer a full repair on Scania, Volvo, Mercedes, Man, Daf and many more.

Connection between a gearbox and drive shaft. Could someone add some picture on connection between a gearbox and drive shaft? —The preceding unsigned comment was added by Mnajib (talk • contribs) 20:31, August 21, 2007 (UTC). Driveshaft material and manufacturing process. What materials are used to make a driveshaft? What manufacturing ANALYSIS OF SPLINE PROFILE AND ITS MANUFACTURING 1Mr. TUMPALA UMA SANTHOSH, 2R Art Babu, 3 Splines are several projections machined on a shaft, the shafts fits into mating bore is called a spline fitting. Spline are made in two forms square and involutes. Spline profiles are mostly important in spline cutting process so the analysis of spline profile is most important in the process of

aluminumcomposite drive shaft was developed with a new manufacturing method, in which a carbon fiber epoxy composite layer was.is being applied to create jet engine shafts. 30 main types of jet engine shafts being produced, primarily for the three global manufacturing.Shaft manufacturing by Riten Industries. propeller shaft manufacturing pdf ANALYSIS OF SPLINE PROFILE AND ITS MANUFACTURING 1Mr. TUMPALA UMA SANTHOSH, 2R Art Babu, 3 Splines are several projections machined on a shaft, the shafts fits into mating bore is called a spline fitting. Spline are made in two forms square and involutes. Spline profiles are mostly important in spline cutting process so the analysis of spline profile is most important in the process of

Development of Additive Manufacturing 1 Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving Development of Additive Manufacturing 1 Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving

iii Contributors Supervising Editor Kyosuke Otoshi Director Chain Products Division Editor Makoto Kanehira Manager Chain Products Division Production Engineering Figure 1-1 Drive train gear transmissions for heavy trucks. a) Scania GRS905R 12+2-speed gearbox with Scania Retarder b) Scania single drive axle (Illustrations from Scania CV AB). This thesis examines process planning and manufacturing of complete gear parts used …

Optimization of a Process Chain for Gear Shaft Manufacturing

An approach for systematic process planning of gear. Propeller Shaft Manufacturing Pdf Download >>> shurll.com/aa8x5, To understand the car manufacturing process, you have to understand the underlying supply chain that drives domestic vehicle assembly. Today's cars are primarily "sourced out" to produce various sub-assemblies in over 4,000 disparate locations as far away as China..

Engineering & Manufacturing Process of a QA1 Carbon Fiber

Shaft manufacturing materials and shaping SlideShare. Endworking Enhances Shaft Manufacturing Process Because endworking is often considered only as a preliminary step for shaft work typical of the automotive industry, potential productivity gains …, Analysis of Drive Shaft 24 ANALYSIS OF DRIVE SHAFT 1BHIRUD PANKAJ PRAKASH, 2 the latest technology and various manufacturing methods has raised application range of these materials. Drive shafts are usually made of solid or hollow tube of steel or aluminum. Over than 70% of single or two-piece differentials are made of several piece propeller shaft that result in a rather heavy drive shaft.

Shaft manufacturing, materials and shaping 1. Shaft manufacturing, materials and shaping Course: Machine Elements 1 Student: Subkhiddin Mukhidinov ID: 47816 2. What is Shaft or Gear? • A shaft or gear is a wheel with teeth that meshes with the teeth of another shaft to transmit power on a continuous basis • Combining shafts of different HGV Shafts & Components. We offer a repair service on all HGV Shafts & stock all components for reapir and modifaction so turn around time is usually within 24hours. No shaft is too big or too small we offer a full repair on Scania, Volvo, Mercedes, Man, Daf and many more.

AmTech International - manufacturing supplier of CNC machining parts, cold forge, hot forging, die casting, stamping, precision gear & shaft manufacturers. However, there is another major source of forces imposed on a crankshaft, namely PistonAcceleration.The combined weight of the piston, ring package, wristpin, retainers, the connecting rod small end and a small amount of oil are being continuously accelerated from rest to very high velocity and back to rest twice each crankshaft revolution.

Development of a High Torque Density, Flexible, Composite Driveshaft Duncan J. Lawrie President Lawrie Technology, Inc. Girard, Pennsylvania duncan@lawrietechnology.com Abstract An all-composite driveshaft incorporating integral flexible diaphragms is described. An approach was explored which obsoletes the split lines and associated fasteners required to attach metallic flex elements and Alibaba.com offers 212 drive shaft manufacturing process products. About 15% of these are machining. A wide variety of drive shaft manufacturing process options are available to you, such as free samples.

02/03/2004 · Drive shaft manufacturing process . United States Patent 6698076 . Abstract: A method of fabricating a driveline assembly including the steps of inserting a first member within a second member, heating the first member to a temperature greater than that of the second member and inserting both members into a die. The inner surface of the die includes an interlocking torque transferring profile Drive Shaft Manufacturing. As a small batch drive shaft manufacturer, we focus on quick response ordering with the potential for custom changes available to meet your production requirements. Our goal is to reduce your inventory, improve your cash flow, and …

Endworking Enhances Shaft Manufacturing Process Because endworking is often considered only as a preliminary step for shaft work typical of the automotive industry, potential productivity gains … Development of a High Torque Density, Flexible, Composite Driveshaft Duncan J. Lawrie President Lawrie Technology, Inc. Girard, Pennsylvania duncan@lawrietechnology.com Abstract An all-composite driveshaft incorporating integral flexible diaphragms is described. An approach was explored which obsoletes the split lines and associated fasteners required to attach metallic flex elements and

China Shaft manufacturers - Select 2020 high quality Shaft products in best price from certified Chinese Bearing manufacturers, Gear Shaft suppliers, wholesalers and factory on Made-in-China.com Development of a High Torque Density, Flexible, Composite Driveshaft Duncan J. Lawrie President Lawrie Technology, Inc. Girard, Pennsylvania duncan@lawrietechnology.com Abstract An all-composite driveshaft incorporating integral flexible diaphragms is described. An approach was explored which obsoletes the split lines and associated fasteners required to attach metallic flex elements and

Engineering & Manufacturing Process. Because we set out to offer the most cutting-edge product in driveshaft technology, every material used and every step performed in manufacturing a QA1 carbon fiber driveshaft has been chosen to bring you the highest-quality driveshaft possible. Watch our video and read below to learn about our manufacturing Connection between a gearbox and drive shaft. Could someone add some picture on connection between a gearbox and drive shaft? —The preceding unsigned comment was added by Mnajib (talk • contribs) 20:31, August 21, 2007 (UTC). Driveshaft material and manufacturing process. What materials are used to make a driveshaft? What manufacturing

26/11/2015 · Licensed to YouTube by AdRev for Rights Holder, AdRev for a 3rd Party (on behalf of Abaco Music Library (5 Alarm Music - Abaco)); ASCAP, LatinAutor, AdRev … AmTech International - manufacturing supplier of CNC machining parts, cold forge, hot forging, die casting, stamping, precision gear & shaft manufacturers.

26/11/2015 · Licensed to YouTube by AdRev for Rights Holder, AdRev for a 3rd Party (on behalf of Abaco Music Library (5 Alarm Music - Abaco)); ASCAP, LatinAutor, AdRev … Ganga Forgings is a well-known Yoke forgings manufacturers in India. With us, you get quality yoke pins, shafts, ball, and body. Our forged yoke manufacturing services are acclaimed worldwide and we provide to you high-quality industrial equipment and components.

Development of Additive Manufacturing 1 Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving Necessity to use new materials, demanding functional requirements and miniaturization have led to evolution of modern manufacturing processes. Developments are taking place both in the conventional methods and unconventional methods of manufacture. High speed machining, hard machining, non conventional processes like beam, mechanical and chemical

An approach for systematic process planning of gear

Splines Spline Cutting Spline Milling Spline Broaching. Analysis of Drive Shaft 24 ANALYSIS OF DRIVE SHAFT 1BHIRUD PANKAJ PRAKASH, 2 the latest technology and various manufacturing methods has raised application range of these materials. Drive shafts are usually made of solid or hollow tube of steel or aluminum. Over than 70% of single or two-piece differentials are made of several piece propeller shaft that result in a rather heavy drive shaft, Endworking Enhances Shaft Manufacturing Process Because endworking is often considered only as a preliminary step for shaft work typical of the automotive industry, potential productivity gains ….

Shaft manufacturing materials and shaping SlideShare

Drive Shaft Manufacturing Process Drive Shaft. Connection between a gearbox and drive shaft. Could someone add some picture on connection between a gearbox and drive shaft? —The preceding unsigned comment was added by Mnajib (talk • contribs) 20:31, August 21, 2007 (UTC). Driveshaft material and manufacturing process. What materials are used to make a driveshaft? What manufacturing https://en.m.wikipedia.org/wiki/Powertrain CV Shafts and Joints used in commercial and taxi operations - 3 months. Claims for replacement of parts will only be processed after inspection and acceptance by the Company and/or its supplier that product is defective in materials or workmanship..

CV Shafts and Joints used in commercial and taxi operations - 3 months. Claims for replacement of parts will only be processed after inspection and acceptance by the Company and/or its supplier that product is defective in materials or workmanship. Ganga Forgings is a well-known Yoke forgings manufacturers in India. With us, you get quality yoke pins, shafts, ball, and body. Our forged yoke manufacturing services are acclaimed worldwide and we provide to you high-quality industrial equipment and components.

US20030129022A1 - Drive shaft manufacturing process - Google Patents Drive shaft manufacturing process Download PDF Info Publication number US20030129022A1. US20030129022A1 US10/040,877 US4087702A US2003129022A1 US 20030129022 A1 US20030129022 A1 US 20030129022A1 US 4087702 A US4087702 A US 4087702A US 2003129022 A1 US2003129022 A1 US 2003129022A1 … Necessity to use new materials, demanding functional requirements and miniaturization have led to evolution of modern manufacturing processes. Developments are taking place both in the conventional methods and unconventional methods of manufacture. High speed machining, hard machining, non conventional processes like beam, mechanical and chemical

ANALYSIS OF SPLINE PROFILE AND ITS MANUFACTURING 1Mr. TUMPALA UMA SANTHOSH, 2R Art Babu, 3 Splines are several projections machined on a shaft, the shafts fits into mating bore is called a spline fitting. Spline are made in two forms square and involutes. Spline profiles are mostly important in spline cutting process so the analysis of spline profile is most important in the process of To understand the car manufacturing process, you have to understand the underlying supply chain that drives domestic vehicle assembly. Today's cars are primarily "sourced out" to produce various sub-assemblies in over 4,000 disparate locations as far away as China.

06/09/2017В В· ODM (Zhejiang ODM Transmission Technology Co., Ltd.) is a Sino-foreign joint venture enterprise with the capability of R&D, designing and manufacturing for C.V. Joints and Drive Shafts. 4. Manufacturing concepts and rationalisation within process planning L6 page 21 4.1 Planning complexity and new manufacturing concepts L6 page 21 4.2 Options for rationalisation in process planning L6 page 22 4.3 Methods for the rationalisation of operations scheduling L6 page 24 5.

iii Contributors Supervising Editor Kyosuke Otoshi Director Chain Products Division Editor Makoto Kanehira Manager Chain Products Division Production Engineering identify the failure cause and condition of the drive shaft. Then do the hardness test to know how hard the material that use in drive shaft. After that we can make an analysis and we try to solve the problem. 1.3 Objectives of Project Analyze the failure of drive shaft that used in Toyota SEG due to the hardness

06/09/2017В В· ODM (Zhejiang ODM Transmission Technology Co., Ltd.) is a Sino-foreign joint venture enterprise with the capability of R&D, designing and manufacturing for C.V. Joints and Drive Shafts. However, there is another major source of forces imposed on a crankshaft, namely PistonAcceleration.The combined weight of the piston, ring package, wristpin, retainers, the connecting rod small end and a small amount of oil are being continuously accelerated from rest to very high velocity and back to rest twice each crankshaft revolution.

Drive shaft Hub Differential gear Stabilizer Drive shaft Knuckle spindle Lower arm Untempered steel Case hardening steel Soft cold forged steel Spring steel Bearing steel [Automobile] 04 05 Automobiles made in Japan are well-known as being No.1 in the world in terms of quality and performance. However, there is another major source of forces imposed on a crankshaft, namely PistonAcceleration.The combined weight of the piston, ring package, wristpin, retainers, the connecting rod small end and a small amount of oil are being continuously accelerated from rest to very high velocity and back to rest twice each crankshaft revolution.

Spline Cutting. Spline cutting is the process of machining internal or external splines (ridges or teeth) onto shafts, gears and other mechanical power transmission components, which mesh with grooves in a mating piece allowing power to be transmitted from one to the other. 4. gear manufacturing 1. Gear Cutting ME 312 Manufacturing TechnologyVikrant Sharma, Mechanical Engineering Department. FET. MITS 2. IntroductionA gear is an important machine elements which is used to for transmission of power or motion or both from one shaft to other. It is normally a round blank carrying projections or teeth along its

4. Manufacturing concepts and rationalisation within process planning L6 page 21 4.1 Planning complexity and new manufacturing concepts L6 page 21 4.2 Options for rationalisation in process planning L6 page 22 4.3 Methods for the rationalisation of operations scheduling L6 page 24 5. 06/09/2017В В· ODM (Zhejiang ODM Transmission Technology Co., Ltd.) is a Sino-foreign joint venture enterprise with the capability of R&D, designing and manufacturing for C.V. Joints and Drive Shafts.

Shaft manufacturing, materials and shaping 1. Shaft manufacturing, materials and shaping Course: Machine Elements 1 Student: Subkhiddin Mukhidinov ID: 47816 2. What is Shaft or Gear? • A shaft or gear is a wheel with teeth that meshes with the teeth of another shaft to transmit power on a continuous basis • Combining shafts of different Alibaba.com offers 212 drive shaft manufacturing process products. About 15% of these are machining. A wide variety of drive shaft manufacturing process options are available to you, such as free samples.

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT . A.Sridhar. 1, Dr. R. Mohan. 2, R.Vinoth Kumar. 3 1. PG Scholar Department – Product Design and Development, Senior Faculty Department of Mechanical Engineering, Sona College of Technology, Salem-636005, Tamil Nadu . 3. Mechanical Faculty in Knowledge Institute of Technology, Salem . ABSTRACT CV Shafts and Joints used in commercial and taxi operations - 3 months. Claims for replacement of parts will only be processed after inspection and acceptance by the Company and/or its supplier that product is defective in materials or workmanship.

Vashikaran Mohini Vidya - Learn A Secert Process to Attract someone you love in seconds pin Mohini vidya vashikaran mantra for love, husband, girl - +9170734318… Mohini mantra in hindi pdf Napier Lane Vashikaran Mohini Vidya - Learn A Secert Process to Attract someone you love in seconds pin Mohini vidya vashikaran mantra for love, husband, girl - +9170734318…