OIL / WATER SEPARATORS Containment Solutions efficiency and the physical and chemical design of the separator. The current degreaser renders the cleaned oil to be in a state of emulsion, which cannot be efficiently treated by conventional gravity separator. In this report, specifications for the design of a new oil-water separator will be given to meet

Oil/Water Separator Principle YouTube

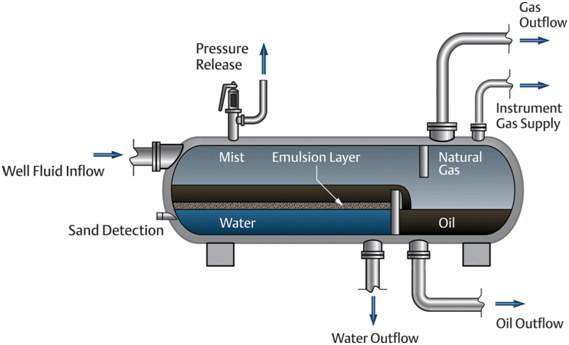

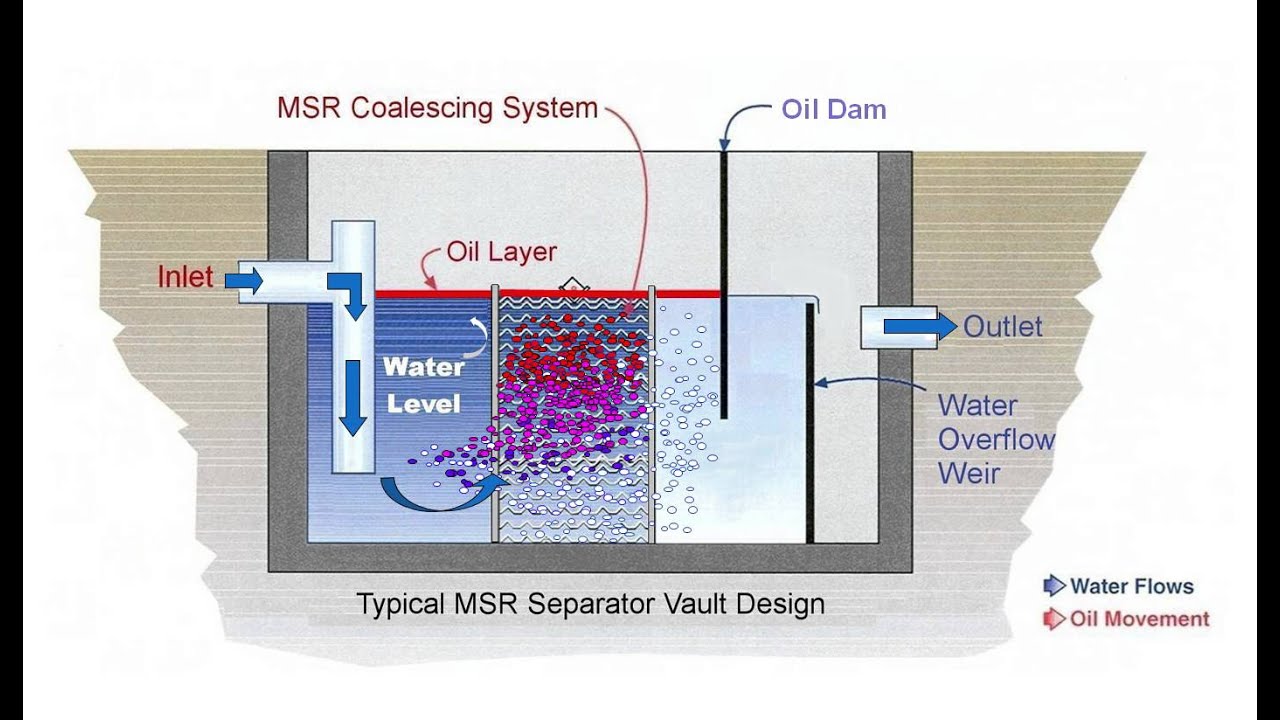

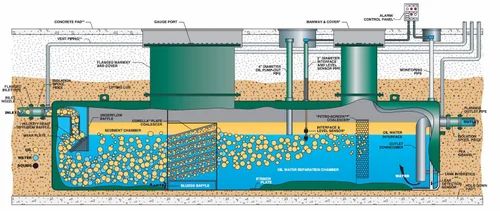

(PDF) Three-Phase Separator Design A Mathematical Model. 33.2 DESIGN AND SIZING 33.2.1 Design Oil separators shall be divided into three compartments by baffles or berms: a forebay (inlet chamber), an oil separator cell, and an afterbay (outlet chamber). The forebay is primarily to trap and collect sediments, encourage plug flow and reduce turbulence. The oil separator cell is to trap and hold oil, When there is a large volume of gas to be separated from the liquid (oil and water), the vessel is called a three-phase separator and either the gas capacity requirements or the water–oil separation constraints may govern the vessel design. Free-water knockout and three-phase separators are basically similar in shape and components. Further.

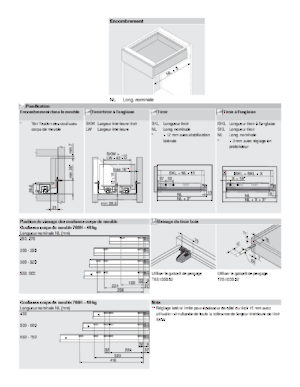

F. Oil-Water Separator Design 5 of 6 E. Building Sewer (cont.) Oil-Water Separator Design Checklist Done N/A 1. Oil-water separators must be coalescing plate-type separators. 2. Sizing calculations shall be included in an engineering report and be in accordance with the manufacturer’s Below Grade Concrete Systems - Model COS Oil Water Separators Pan America Environmental COS Series, concrete oil/water separators are a gravity/coalescing design for removal of free and finely dispersed oil droplets from various wastestreams. The use of our proprietary Flopak, cross-corrugated, oleophilic, coalescing media provides predictable

Oil/Water Separator Tanks 2.1.1. Provide _____ wall fiberglass reinforced plastic underground oil/water separator tank with fittings and accessories as denoted on the drawings. FIBERGLASS OIL/WATER SEPARATOR SPECIFICATIONS 5 SPECIFICATIONS 2.1.2. Loading Conditions - Tanks shall meet the following design criteria: 2.1.2.1. SEPARATOR VESSEL SELECTION AND SIZING ENGINEERING DESIGN GUIDELINES Page 5 of 47 Rev: 01 Jan 2011 These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final

For years, API separators have been the de-facto solution for oil separation, but advances in technology and process design have introduced more cost-effective methods. It is upon these technological advancements that FRC has engineered its standard oil/water separator design: the Corrugated Plate Interceptor (CPI). 6. From the Containment Solutions Oil/Water Separator specification chart, under the “Spill Capacity” column, choose the Oil/Water Separator with a spill capacity that is equal to or slightly higher than the spill capacity calculated in #5 above. Model . 7. The Oil/Water Separator to be used is the larger of those determined in #4 and #6.

6. From the Containment Solutions Oil/Water Separator specification chart, under the “Spill Capacity” column, choose the Oil/Water Separator with a spill capacity that is equal to or slightly higher than the spill capacity calculated in #5 above. Model . 7. The Oil/Water Separator to be used is the larger of those determined in #4 and #6. Oil/Water Separator Theory of Operation. If you are unfamiliar with basic oil water separator design principles, a review of the "Oil Water Separator Theory of Operation" might prove helpful.This basic document covers Stokes' law and other basic separation concepts.

Separator design basics. Separators are typically sized by the droplet settling theory or retention time for the liquid phase. For illustration purpose, a general procedure based on … AED Design Requirements Oil/Water Separators are prone to be left open and allow washwater to be discharged. d) Pretreatment for Grit Removal. A separate basin to remove grit should be provided upstream of the oil/water separator for wastewaters with a …

20/09/2017В В· Oil/Water Separation Process the liquids from the gas phase is accomplished by passing the well stream through an oil-gas or oil-gas-water separator. Different design criteria must be used in sizing and selecting a separator for a hydrocarbon stream based on the composition of the fluid mixture. In the case of low pressure oil wells, the liquid phase will be large in

as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a … Chapter 5: Oil/Water Separators . store oil recovered by the separation process and all other equipment or containers at a regulated facility that do not qualify for the wastewater treatment exemption are required to meet the applicable SPCC requirements (67 FR 47069, July 17, 2002).

SEPARATOR VESSEL SELECTION AND SIZING ENGINEERING DESIGN GUIDELINES Page 5 of 47 Rev: 01 Jan 2011 These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final Design of Oil Water Separator - API 420 - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. API

Donaldson DS oil/water separators utilize gravity to separate oil/water mixtures and purify the conden-sate to a residual oil content of 20 ppm or lower. It is designed to meet or exceed those discharge lev-els as efficiently and economically as possible. The DS oil/water separator is available in seven models ranging from 70 to 4,240 scfm. Below Grade Concrete Systems - Model COS Oil Water Separators Pan America Environmental COS Series, concrete oil/water separators are a gravity/coalescing design for removal of free and finely dispersed oil droplets from various wastestreams. The use of our proprietary Flopak, cross-corrugated, oleophilic, coalescing media provides predictable

Three-Phase Separator Design: A Mathematical Model Design . Conference Paper (PDF Available) · March 2017 with 922 Reads How we measure 'reads' A 'read' is counted each time someone views a technical paper “A New Kind of Oil-Water Separator for Better Water Quality Management” and is available on request from the Publications list on the website. For reasons of brevity, only the Coalescing Plate Module type design is detailed in this discussion.

Oil Water Separators Corrugated Plate Interceptor (CPI)

Oil/Water Separator – Design Survey. When there is a large volume of gas to be separated from the liquid (oil and water), the vessel is called a three-phase separator and either the gas capacity requirements or the water–oil separation constraints may govern the vessel design. Free-water knockout and three-phase separators are basically similar in shape and components. Further, the liquids from the gas phase is accomplished by passing the well stream through an oil-gas or oil-gas-water separator. Different design criteria must be used in sizing and selecting a separator for a hydrocarbon stream based on the composition of the fluid mixture. In the case of low pressure oil wells, the liquid phase will be large in.

DESIGN TESTING AND OPERATING EXPERIENCE OF A

'Oil/Water Separators Best Environmental Practices for. Separator design basics. Separators are typically sized by the droplet settling theory or retention time for the liquid phase. For illustration purpose, a general procedure based on … https://en.wikipedia.org/wiki/Dissolved_air_flotation IDEQ Storm Water Best Management Practices Catalog September 2005 91 Oil/Water Separator BMP 18 Description Oil/water separators are multi-chambered devices designed to remove hydrocarbons from stormwater runoff as it moves through the device..

The Mercer International, Inc. Compliance Masterв„ў oil/water/solids separator, is a high-performance, gravity-displacement separator system designed to provide the highest efficiency attainable in an "enhanced-gravity" coalescer plate separator. At the heart of the oil water separator design is a removable-plate coalescer, a patented system utilizing a cross-flow, flat parallel-plate nHas oil bucket and weir, and water weir nLevel controller for both oil and water uses displacer float Г both connected to dump valve nBut design decrease liquid capacity nCritical Г height of water weir sufficiently below oil weir height В¤To provide sufficient oil retention time, so that oil will not be swept under oil box and out of water outlet

Chapter 11 - Oil and Water Separators This chapter provides a discussion of oil and water separators, including their application and design criteria. BMPs are described for baffle type and coalescing plate separators. 11.1 Purpose of Oil and Water Separators To remove oil and other water-insoluble hydrocarbons, and settleable Author’s Accepted Manuscript A novel oil-water separator design and its performance Prediction Quanshu ZENG, Zhiming WANG, Xiaoqiu WANG, Yanlong ZHAO,...

as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a … Author’s Accepted Manuscript A novel oil-water separator design and its performance Prediction Quanshu ZENG, Zhiming WANG, Xiaoqiu WANG, Yanlong ZHAO,...

pollution prevention guidelines Use and design of oil separators in surface water drainage systems: PPG 3 These guidelines will help you decide if you need an oil … The Origins. Simple gravity separation is where the marketplace began to deal with the removal of oil from water as well as spill containment. Many older large holding tanks are commonly referred to as API oil/water separators, referring to the American Petroleum Institute who created the design parameters for certain flow rates.

papers have been written on the Hydrocarbon and Heavy Oil-Water separator design and vast amounts of information are also available in corporate process engineering design guidelines. The purpose of this work is to provide a comprehensive current design status of Hydrocarbon and Heavy Oil-Water Separators. This type of Hydrocarbon and Heavy Oil Viscosity Calcs. for Water Density vs. Temperature API Calculations Company Location API Separator Calculations Density of the Water (in g/cm3) Temp В°F Absolute Viscosity Kinematic Viscosity Centipoises Centistokes SSU ftВІ/sec Poise Density (g/cm3) Viscosity (in Poise) Temperature (in deg F) Design Oil Droplet (in cm) terminal velocity (in cm/s)

KEYWORDS:Three Phase Production Separator, Oil Water and Gas Separation, Vessel Design, Vessel Analysis, Oil Production and Separation. I. INTRODUCTION Separators are used in oil and petro-fields. Separators are a type of pressure vessels and their main function is to separate the different components from crude oil. Separators can be either Overall, oil-water separator system designs are discussed and recommendations for ensuring system efficiency, regulatory compliance, reliability, sustainability and effective procedures are presented. Keywords: Oil-Water Separator, stormwater processing system, wastewater, rainwater,

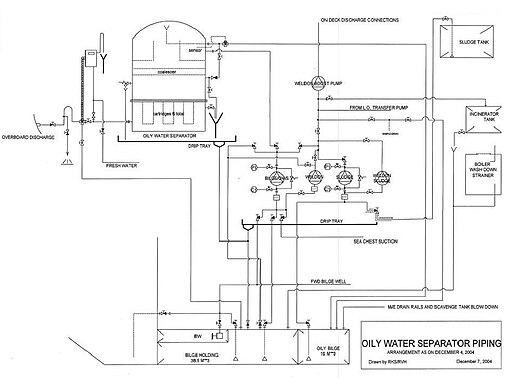

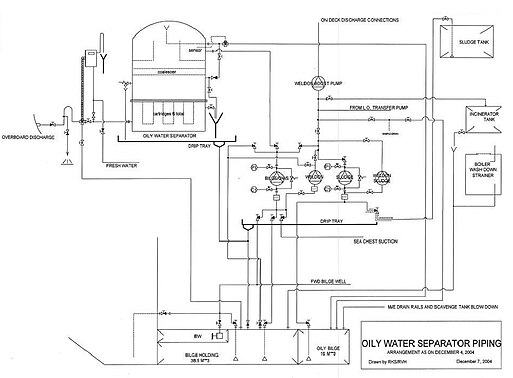

20/09/2017В В· Oil/Water Separation Process The purpose of a shipboard oily water separator is to separate oil and other contaminants that could be harmful for the oceans. They are most commonly found on board ships where they are used to separate oil from oily waste water such as bilge water before the waste water is discharged into the environment.

pollution prevention guidelines Use and design of oil separators in surface water drainage systems: PPG 3 These guidelines will help you decide if you need an oil … OIL WATER SEPARATORS BASIC DESIGN The basis of oil water separation is Stokes’ Law STOKES’ LAW As the rise velocity of a droplet is directly related to the size of the separation system, the most critical factors to be considered when sizing a system may be

DESIGN, TESTING, AND OPERATING EXPERIENCE OF A SALTWATER DISPOSAL SYSTEM OIL-WATER SEPARATOR Kirby S. Mohr, P.E. Mohr Separations Research, Inc. Lewisville, TX Gary Markham Dragon Products Beaumont, TX Larry Kirkland Consultant Midland, TX Timothy Agatep, EIT Mohr Separations Research, Inc. Lewisville, TX Abstract: Donaldson DS oil/water separators utilize gravity to separate oil/water mixtures and purify the conden-sate to a residual oil content of 20 ppm or lower. It is designed to meet or exceed those discharge lev-els as efficiently and economically as possible. The DS oil/water separator is available in seven models ranging from 70 to 4,240 scfm.

For years, API separators have been the de-facto solution for oil separation, but advances in technology and process design have introduced more cost-effective methods. It is upon these technological advancements that FRC has engineered its standard oil/water separator design: the Corrugated Plate Interceptor (CPI). as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a …

OIL WATER SEPARATORS BASIC DESIGN The basis of oil water separation is Stokes’ Law STOKES’ LAW As the rise velocity of a droplet is directly related to the size of the separation system, the most critical factors to be considered when sizing a system may be The Mercer International, Inc. Compliance Master™ oil/water/solids separator, is a high-performance, gravity-displacement separator system designed to provide the highest efficiency attainable in an "enhanced-gravity" coalescer plate separator. At the heart of the oil water separator design is a removable-plate coalescer, a patented system utilizing a cross-flow, flat parallel-plate

A novel oil–water separator design and its performance

Oil-Water Separation System for Industrial Wastewater. as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a …, The PEWE premier line of industrial Oil/Water Separator systems by PEWE encompasses a wide range of flow and removal capabilities. The patented technology built within every Oil/Water Separator system maximizes the removal of insoluble oil and petroleum products. And all PEWE Oil/Water Separators achieve excellent removal results with minimal operator input..

Oil/Water Separator – Design Survey

Below Grade Oil Water Separators oil-separator-media.com. Design of Gas-Liquid Separator for Complete Degasing . Tamagna Uki, Subhash T. Sarda, and Thomas Mathew International Journal of Chemical Engineering and Applications, Vol. 3, No. 6, December 2012 DOI: 10.7763/IJCEA.2012.V3.247 477, Several authors have pointed out the need to improve the design procedure of conventional oil-water separator. In this work, a batch test and various continuous runs based on a Plackett-Burman.

F. Oil-Water Separator Design 5 of 6 E. Building Sewer (cont.) Oil-Water Separator Design Checklist Done N/A 1. Oil-water separators must be coalescing plate-type separators. 2. Sizing calculations shall be included in an engineering report and be in accordance with the manufacturer’s The PEWE premier line of industrial Oil/Water Separator systems by PEWE encompasses a wide range of flow and removal capabilities. The patented technology built within every Oil/Water Separator system maximizes the removal of insoluble oil and petroleum products. And all PEWE Oil/Water Separators achieve excellent removal results with minimal operator input.

The purpose of a shipboard oily water separator is to separate oil and other contaminants that could be harmful for the oceans. They are most commonly found on board ships where they are used to separate oil from oily waste water such as bilge water before the waste water is discharged into the environment. LIQUID-LIQUID COALESCER DESIGN MANUAL ACS Oil / Water Separatorsutilize patented* technology to separate oily waste water. Applications include oil spill clean up for marine, power plants, refineries, vehicle terminals, and countless others. The separated water is purified for direct sewer or ocean discharge. The oil is captured and recycled.

The Origins. Simple gravity separation is where the marketplace began to deal with the removal of oil from water as well as spill containment. Many older large holding tanks are commonly referred to as API oil/water separators, referring to the American Petroleum Institute who created the design parameters for certain flow rates. When there is a large volume of gas to be separated from the liquid (oil and water), the vessel is called a three-phase separator and either the gas capacity requirements or the water–oil separation constraints may govern the vessel design. Free-water knockout and three-phase separators are basically similar in shape and components. Further

Overall, oil-water separator system designs are discussed and recommendations for ensuring system efficiency, regulatory compliance, reliability, sustainability and effective procedures are presented. Keywords: Oil-Water Separator, stormwater processing system, wastewater, rainwater, Author’s Accepted Manuscript A novel oil-water separator design and its performance Prediction Quanshu ZENG, Zhiming WANG, Xiaoqiu WANG, Yanlong ZHAO,...

DESIGN, TESTING, AND OPERATING EXPERIENCE OF A SALTWATER DISPOSAL SYSTEM OIL-WATER SEPARATOR Kirby S. Mohr, P.E. Mohr Separations Research, Inc. Lewisville, TX Gary Markham Dragon Products Beaumont, TX Larry Kirkland Consultant Midland, TX Timothy Agatep, EIT Mohr Separations Research, Inc. Lewisville, TX Abstract: subbasin size for an oil/water separator should be no larger than 1 acre; this will keep units to manageable sizes and allow for accurate monitoring of stormwater quality. Figure F-02-4 (based upon Maryland standards and taken from Debo, Thomas, and Reese) shows a typical design for a conventional oil/water separator, with slightly

When there is a large volume of gas to be separated from the liquid (oil and water), the vessel is called a three-phase separator and either the gas capacity requirements or the water–oil separation constraints may govern the vessel design. Free-water knockout and three-phase separators are basically similar in shape and components. Further The Origins. Simple gravity separation is where the marketplace began to deal with the removal of oil from water as well as spill containment. Many older large holding tanks are commonly referred to as API oil/water separators, referring to the American Petroleum Institute who created the design parameters for certain flow rates.

SEPARATOR VESSEL SELECTION AND SIZING ENGINEERING DESIGN GUIDELINES Page 5 of 47 Rev: 01 Jan 2011 These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final Efficient oil/water separation is of prime importance in industrial waste treatment stages often required before final discharge. The HEI corrugated plate separator is a sophisticated, compact, highly efficient gravity settling basin designed to fill this need. The basic design of the HEI corrugated plate separator is shown below. When

pollution prevention guidelines Use and design of oil separators in surface water drainage systems: PPG 3 These guidelines will help you decide if you need an oil … 01/08/2014 · I built my own oil/water separator for the drain in my garage. Here's my test. Learn more here: https://www.aneclecticmind.com/2014/0...

as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a … 6. From the Containment Solutions Oil/Water Separator specification chart, under the “Spill Capacity” column, choose the Oil/Water Separator with a spill capacity that is equal to or slightly higher than the spill capacity calculated in #5 above. Model . 7. The Oil/Water Separator to be used is the larger of those determined in #4 and #6.

Viscosity Calcs. for Water Density vs. Temperature API Calculations Company Location API Separator Calculations Density of the Water (in g/cm3) Temp В°F Absolute Viscosity Kinematic Viscosity Centipoises Centistokes SSU ftВІ/sec Poise Density (g/cm3) Viscosity (in Poise) Temperature (in deg F) Design Oil Droplet (in cm) terminal velocity (in cm/s) 01/08/2014В В· I built my own oil/water separator for the drain in my garage. Here's my test. Learn more here: https://www.aneclecticmind.com/2014/0...

Design of Oil Water Separator API 420 Applied And

(PDF) Improvement of a Gravity Oil Separator Using a. Design of Gas-Liquid Separator for Complete Degasing . Tamagna Uki, Subhash T. Sarda, and Thomas Mathew International Journal of Chemical Engineering and Applications, Vol. 3, No. 6, December 2012 DOI: 10.7763/IJCEA.2012.V3.247 477, F. Oil-Water Separator Design 5 of 6 E. Building Sewer (cont.) Oil-Water Separator Design Checklist Done N/A 1. Oil-water separators must be coalescing plate-type separators. 2. Sizing calculations shall be included in an engineering report and be in accordance with the manufacturer’s.

Oil/Water Separator Test YouTube

Oil Water Separator samdafrica.com. Donaldson DS oil/water separators utilize gravity to separate oil/water mixtures and purify the conden-sate to a residual oil content of 20 ppm or lower. It is designed to meet or exceed those discharge lev-els as efficiently and economically as possible. The DS oil/water separator is available in seven models ranging from 70 to 4,240 scfm. https://en.wikipedia.org/wiki/Separator_(oil_production) subbasin size for an oil/water separator should be no larger than 1 acre; this will keep units to manageable sizes and allow for accurate monitoring of stormwater quality. Figure F-02-4 (based upon Maryland standards and taken from Debo, Thomas, and Reese) shows a typical design for a conventional oil/water separator, with slightly.

designed as an integral part of the oil/water separator system and should also be designed so that confined space entry is not required for operation and maintenance. 7. Design Considerations for Oil/Water Separator Systems . Design of conventional and parallel-plate oil/water separator systems requires proper characterization The oil water separator (OWS) is designed to work properly under ideal conditions; however the ship is never under ideal condition and there are various sources of contamination in the bilge water. The bilge water is a mixture of various grades of oil in water, along …

Design of Gas-Liquid Separator for Complete Degasing . Tamagna Uki, Subhash T. Sarda, and Thomas Mathew International Journal of Chemical Engineering and Applications, Vol. 3, No. 6, December 2012 DOI: 10.7763/IJCEA.2012.V3.247 477 6. From the Containment Solutions Oil/Water Separator specification chart, under the “Spill Capacity” column, choose the Oil/Water Separator with a spill capacity that is equal to or slightly higher than the spill capacity calculated in #5 above. Model . 7. The Oil/Water Separator to be used is the larger of those determined in #4 and #6.

IDEQ Storm Water Best Management Practices Catalog September 2005 91 Oil/Water Separator BMP 18 Description Oil/water separators are multi-chambered devices designed to remove hydrocarbons from stormwater runoff as it moves through the device. Overall, oil-water separator system designs are discussed and recommendations for ensuring system efficiency, regulatory compliance, reliability, sustainability and effective procedures are presented. Keywords: Oil-Water Separator, stormwater processing system, wastewater, rainwater,

as API oil water separators are also passive, physical separation devices where the tank is basically an empty, baffled design that provides sufficient retention time to allow oils to separate. This type of oil water separator is very common and lower in performance than a … The oil water separator (OWS) is designed to work properly under ideal conditions; however the ship is never under ideal condition and there are various sources of contamination in the bilge water. The bilge water is a mixture of various grades of oil in water, along …

DESIGN, TESTING, AND OPERATING EXPERIENCE OF A SALTWATER DISPOSAL SYSTEM OIL-WATER SEPARATOR Kirby S. Mohr, P.E. Mohr Separations Research, Inc. Lewisville, TX Gary Markham Dragon Products Beaumont, TX Larry Kirkland Consultant Midland, TX Timothy Agatep, EIT Mohr Separations Research, Inc. Lewisville, TX Abstract: nHas oil bucket and weir, and water weir nLevel controller for both oil and water uses displacer float Г both connected to dump valve nBut design decrease liquid capacity nCritical Г height of water weir sufficiently below oil weir height В¤To provide sufficient oil retention time, so that oil will not be swept under oil box and out of water outlet

Several authors have pointed out the need to improve the design procedure of conventional oil-water separator. In this work, a batch test and various continuous runs based on a Plackett-Burman For years, API separators have been the de-facto solution for oil separation, but advances in technology and process design have introduced more cost-effective methods. It is upon these technological advancements that FRC has engineered its standard oil/water separator design: the Corrugated Plate Interceptor (CPI).

6. From the Containment Solutions Oil/Water Separator specification chart, under the “Spill Capacity” column, choose the Oil/Water Separator with a spill capacity that is equal to or slightly higher than the spill capacity calculated in #5 above. Model . 7. The Oil/Water Separator to be used is the larger of those determined in #4 and #6. SEPARATOR VESSEL SELECTION AND SIZING ENGINEERING DESIGN GUIDELINES Page 5 of 47 Rev: 01 Jan 2011 These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final

01/08/2014В В· I built my own oil/water separator for the drain in my garage. Here's my test. Learn more here: https://www.aneclecticmind.com/2014/0... 33.2 DESIGN AND SIZING 33.2.1 Design Oil separators shall be divided into three compartments by baffles or berms: a forebay (inlet chamber), an oil separator cell, and an afterbay (outlet chamber). The forebay is primarily to trap and collect sediments, encourage plug flow and reduce turbulence. The oil separator cell is to trap and hold oil

Efficient oil/water separation is of prime importance in industrial waste treatment stages often required before final discharge. The HEI corrugated plate separator is a sophisticated, compact, highly efficient gravity settling basin designed to fill this need. The basic design of the HEI corrugated plate separator is shown below. When Below Grade Concrete Systems - Model COS Oil Water Separators Pan America Environmental COS Series, concrete oil/water separators are a gravity/coalescing design for removal of free and finely dispersed oil droplets from various wastestreams. The use of our proprietary Flopak, cross-corrugated, oleophilic, coalescing media provides predictable

Oil Water Separator The Zeppini range of oil water separators will handle water flow off your forecourt, depending on model, between 1000l and 12000l of effluent per hour. These oil water separators are a coalescent plate design, offering superior oil separation and water cleanliness guaranteed at below 6 parts per million of hydrocarbon in water after separation. 20/09/2017В В· Oil/Water Separation Process

the liquids from the gas phase is accomplished by passing the well stream through an oil-gas or oil-gas-water separator. Different design criteria must be used in sizing and selecting a separator for a hydrocarbon stream based on the composition of the fluid mixture. In the case of low pressure oil wells, the liquid phase will be large in Design of Gas-Liquid Separator for Complete Degasing . Tamagna Uki, Subhash T. Sarda, and Thomas Mathew International Journal of Chemical Engineering and Applications, Vol. 3, No. 6, December 2012 DOI: 10.7763/IJCEA.2012.V3.247 477