lag bolt size chart pdf

Get the ultimate lag bolt size chart PDF! Find sizes, lengths, and diameters in an easy-to-read format. Perfect for construction and DIY projects. Download now from Jeremy Machattie!

Lag bolts are essential for securing heavy-duty applications, ensuring structural integrity in construction and woodworking. Their size charts provide critical specifications for diameters, thread lengths, and head sizes.

Understanding lag bolt sizing is crucial for safe and effective fastening, preventing over-tightening and ensuring proper fit. This guide offers detailed charts and specifications for optimal results.

1.1 Overview of Lag Bolts

Lag bolts, also known as lag screws, are large, heavy-duty fasteners used to secure heavy materials like wood and metal. They feature a thick, threaded shank and a hex head for tightening with a wrench. Unlike regular screws, lag bolts are designed to grip deeply into materials, providing exceptional holding power. They are commonly used in construction, furniture making, and woodworking projects. Lag bolts come in various sizes, materials, and thread lengths, making size charts essential for selecting the right bolt for the job. Proper sizing ensures safety and structural integrity.

1.2 Importance of Size Charts

Lag bolt size charts are crucial for ensuring proper fastener selection, as they provide precise measurements for diameter, thread length, and head size. Using the correct size prevents over-tightening and ensures a secure fit, reducing the risk of material damage. These charts also help in selecting the appropriate material and finish for specific applications. By referencing size charts, users can avoid errors and ensure structural integrity, making them indispensable for both professionals and DIY projects. Proper sizing is key to safety and durability in any construction or woodworking task.

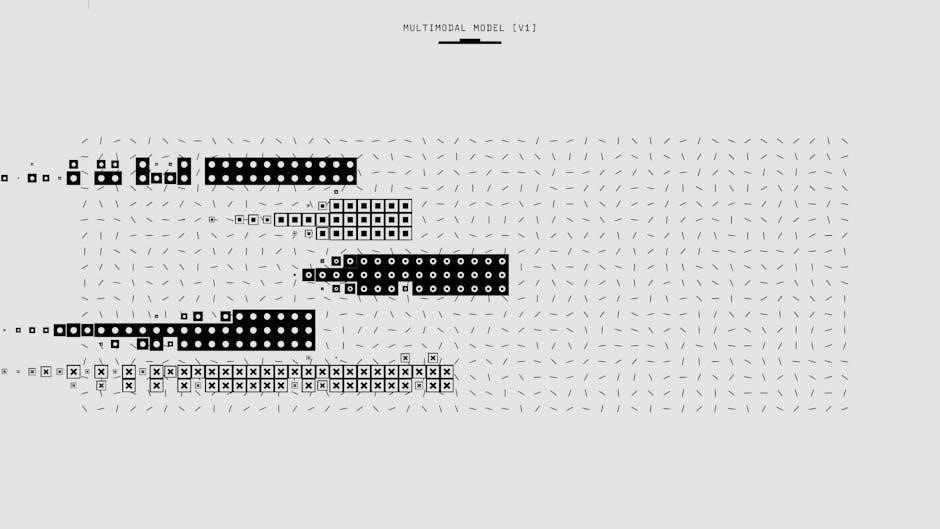

Understanding Lag Bolt Size Charts

Lag bolt size charts provide detailed specifications for diameters, lengths, and thread lengths, ensuring proper fastener selection for various applications. They are essential for accurate project planning.

2.1 Standard Bolt Sizes (US)

Standard bolt sizes in the US are categorized by nominal diameter, ranging from 1/4″ to 1 1/2″. These sizes are defined by ASME B18.2.1 standards, ensuring consistency across applications.

Charts typically list body diameter, thread length, and head dimensions. For example, a 1/4″ lag bolt has a 7/16″ hex head, while a 3/8″ bolt features a 9/16″ head; These specifications guide proper fastener selection.

2.2 Hex Head Lag Screw Common Sizes

Hex head lag screws are available in various sizes, with common diameters ranging from 1/4″ to 1 1/2″. The head size increases proportionally with the bolt diameter.

For instance, a 1/4″ lag screw has a 7/16″ hex head, while a 5/16″ screw features a 1/2″ head. A 3/8″ lag screw includes a 9/16″ hex head, and a 1/2″ screw has a 3/4″ head; These sizes are widely used for structural applications.

Key Specifications

Key specifications include nominal diameter, body diameter, width across flats, and thread length. These measurements ensure proper fit and structural integrity in various applications.

3.1 Nominal Size or Basic Product Diameter

The nominal size, or basic product diameter, is the labeled or identified size of the lag bolt. It is a critical dimension, as it determines the thread length and head size. This measurement must match the pilot hole diameter to ensure proper fit and avoid splitting wood. The nominal size is typically listed in lag bolt size charts and is essential for selecting the correct fastener for your project, ensuring structural integrity and safety.

3.2 Body Diameter

The body diameter refers to the unthreaded portion of the lag bolt, which is typically the same as or slightly larger than the nominal size. This measurement is crucial, as it determines the fit within the pilot hole. A larger body diameter can affect the structural integrity of the material being fastened. Proper alignment and sizing ensure the bolt functions as intended, providing stability and strength to the connection. Always consult the chart to match the body diameter with the intended application for optimal results.

3.3 Width Across Flats

The width across flats is the distance between two parallel flats on the hex head of a lag bolt. This measurement is critical for tool fitment, as wrenches or sockets must match this dimension for proper tightening. The width across flats is typically slightly larger than the nominal size of the bolt. For example, a 1/4-inch lag bolt has a width across flats of 7/16 inch. Always refer to the size chart to ensure compatibility with your tools and applications, as incorrect sizing can lead to stripped heads or improper tightening.

3.4 Width Across Corners

The width across corners measures the distance between two opposite corners of the hex head. It is larger than the width across flats due to the hexagonal geometry. For example, a 1/4-inch lag bolt typically has a width across corners of approximately 9/16 inch. Always refer to the size chart for exact measurements, as this dimension ensures proper fitment in applications where the hex head’s diagonal is a consideration. Accurate sizing is essential for both functionality and safety in construction projects.

3.5 Head Height

Head height refers to the vertical distance from the top of the hex head to the bearing surface. For a 1/4-inch lag bolt, this measurement is approximately 13/64 inch. The height ensures proper seating and prevents over-tightening. For larger bolts, such as a 1/2-inch diameter, the head height increases to about 25/64 inch. This dimension is crucial for ensuring the bolt sits flush without protruding excessively. Always consult the size chart for precise measurements to match your specific application requirements.

3.6 Thread Length

Thread length is the distance from the tip of the lag bolt to the end of the threaded portion. It is critical for ensuring proper engagement with the material. For a 1/4-inch lag bolt, the thread length is typically 1 inch, while a 3/8-inch bolt may have 1.5 inches of threads. Longer threads provide better hold in denser materials. Always refer to the size chart to match the thread length with your application, ensuring adequate grip without over-engagement. Proper thread length enhances structural integrity and prevents stripping or loosening over time.

Application and Usage

Lag bolts are ideal for heavy-duty fastening, commonly used in construction and woodworking. Their application ensures strong holds in dense materials, with size selection crucial for project success.

4.1 Real-Life Lag Screw Size Application

In practical scenarios, selecting the right lag screw size involves measuring the combined width of the materials to be fastened. Typically, a lag bolt should be 1/4 inch shorter than the total thickness of the materials. For instance, if fastening two 2-inch thick lumber pieces, a 3.5-inch lag bolt is appropriate. Using a lag bolt that’s too long can cause material splitting, while one that’s too short may not provide sufficient hold. Proper sizing ensures structural integrity and prevents damage to the material.

4.2 Typical Application Scenarios

Lag bolts are commonly used in decking, fencing, and heavy-duty construction projects. They are ideal for securing large wooden beams, metal frames, and load-bearing structures. For example, in decking, lag bolts are used to attach railings to posts, ensuring stability and safety. In fencing, they secure posts to concrete footings or wooden frames. For heavier applications, such as attaching wooden lagging to steel soldier piles, larger diameters like 3/8 inches or more are often required. Always refer to size charts to ensure proper bolt selection for your project’s demands.

Pilot Hole Sizes for Lag Screws

Pilot hole sizes are crucial to prevent wood splitting and ensure proper screw seating. Typical diameters range from 1/8 inch to 1/4 inch, depending on screw size.

5.1 Pilot Hole Diameter Recommendations

Pilot hole diameters for lag screws are typically 1/8 inch to 1/4 inch, depending on the screw size and wood type. Proper sizing prevents splitting and ensures tight fits. Always drill pilot holes slightly smaller than the screw’s body diameter to avoid over-sizing. For precise guidance, consult the lag bolt size chart PDF, which provides exact measurements for various screw diameters and lengths. This ensures optimal installation and prevents material damage. Accurate pilot holes are critical for secure fastening and structural integrity.

5.2 Wood Type Considerations

Wood type significantly impacts pilot hole sizing and lag bolt performance. Softwoods, like pine, require slightly larger pilot holes than hardwoods, such as oak, due to differences in density. Moisture content and grain direction also influence hole sizing and screw holding power. The lag bolt size chart PDF provides tailored recommendations for various wood species, ensuring proper fit and preventing splitting. Adhering to these guidelines enhances the structural integrity and longevity of the fastened assembly. Always consider wood type when selecting lag bolt sizes for optimal results.

Load Capacity and Strength

Lag bolts’ load capacity and strength depend on factors like wood type, grain direction, and bolt characteristics. Proper sizing ensures maximum holding power and structural reliability.

6.1 Lateral Design Strength

Lateral design strength refers to a lag bolt’s ability to resist shear forces when loaded perpendicularly to its axis. This strength is influenced by factors like wood type, grain direction, and bolt characteristics. For example, bolts in parallel-to-grain orientations typically exhibit higher lateral strength compared to perpendicular orientations. Technical data often specifies lateral design strength in pounds, with values varying based on bolt size and material. Proper sizing ensures the bolt can withstand expected loads without failure.

- Offset Yield Load (OYL) impacts lateral strength calculations.

- Thread-in-shear and shank-in-shear scenarios affect load capacity.

- Wood density and moisture content also play critical roles.

For instance, a 1/2″ lag bolt might have an OYL of 650 lbs and a lateral design strength of 1,200 lbs in parallel-to-grain applications, dropping to 900 lbs in perpendicular-to-grain scenarios. Always consult charts for precise values.

6.2 Withdrawal Capacity

Withdrawal capacity refers to the maximum force a lag bolt can resist when being pulled out of the material it is anchored in. This capacity depends on wood density, moisture content, and bolt characteristics like thread length and diameter. For example, a 1/2″ lag bolt in dense hardwood might have a withdrawal capacity of 1,500 lbs, while in softwood, it could be significantly lower. Charts provide specific values based on these factors to ensure safe and reliable fastening. Always consult the lag bolt size chart for precise calculations.

Formula: Withdrawal Capacity = (Thread Length × Diameter × Wood Density) ÷ Safety Factor.

Construction and Material

Lag bolts feature full body diameter or thread-in-shear constructions, enhancing strength and durability. Materials like zinc or stainless steel ensure corrosion resistance and longevity in various environments.

7.1 Full Body Diameter Lag Screws

Full body diameter lag screws feature a uniform diameter throughout their length, with an unthreaded shank and a threaded portion near the tip. They are designed for strength and stability in woodworking applications. The unthreaded shank allows for smooth insertion into pre-drilled pilot holes, while the threaded section provides secure anchorage. Proper sizing ensures optimal performance, with calculations often involving the combined width of materials and the screw’s length. For example, a 3/8″ diameter lag screw requires careful measurement to avoid over-tightening. Always consult size charts for precise specifications.

7.2 Thread-in-Shear and Shank-in-Shear

Thread-in-shear and shank-in-shear are critical design considerations for lag screws. Thread-in-shear refers to the portion of the screw that resists shear forces through its threaded section, while shank-in-shear involves the unthreaded portion resisting shear stress. Both mechanisms are essential for ensuring the structural integrity of connections. The unthreaded shank allows for smooth insertion into pre-drilled pilot holes, while the threaded section provides anchorage. Proper sizing and material selection are vital to avoid failure under load, with factors like wood type and grain direction influencing performance.

Security and Specialty Bolts

Security lag bolts, like Penta Head, offer enhanced tamper resistance. Specialty bolts cater to unique applications, ensuring durability and adaptability for heavy-duty or custom projects, with precise sizing charts available.

8.1 Penta Head Security Lag Bolt

The Penta Head Security Lag Bolt offers enhanced security with its unique five-sided head, resisting tampering. Designed for high-strength applications, it features precise sizing charts for diameter and thread length. Ideal for construction and heavy-duty projects, its tamper-resistant design ensures reliability and safety; Available in various materials, including stainless steel, it provides durability and corrosion resistance. Detailed specifications and size charts are available for accurate selection, ensuring optimal performance in secure environments.

8.2 Offset Yield Load and Technical Data

Offset yield load refers to the maximum force a lag bolt can withstand before deforming. Technical data sheets provide critical specifications, including lateral design strength and withdrawal capacity. For example, a 0.4 multiplier applies to thread-in-shear scenarios, while 0.65 is used for shank-in-shear applications. These values vary based on wood type and grain direction. Ensure proper selection by consulting the technical data sheet for construction lag screws, which outlines load capacities and material specifications to ensure safe and reliable fastening solutions.

Tools and Resources

Printable standard bolt size charts and hex head lag screw head size charts are essential tools for selecting the right fasteners. These resources provide detailed dimensions and specifications.

9.1 Printable Standard Bolt Size Chart PDF

A printable standard bolt size chart PDF is a valuable resource for engineers and DIYers alike, providing clear and comprehensive sizing information. These charts detail nominal sizes, body diameters, thread lengths, and head dimensions, ensuring accurate bolt selection. They are organized by standard specifications, such as ASME B18.2.1, and cover a wide range of bolt sizes. This tool is indispensable for verifying measurements and ensuring compatibility in various projects, from construction to furniture making.

9.2 Hex Head Lag Screw Head Size Chart

A hex head lag screw head size chart offers precise measurements for head dimensions relative to screw diameters. For instance, a 1/4″ diameter screw has a 7/16″ head size, while a 1/2″ screw features a 3/4″ head. These charts are essential for ensuring proper wrench fitment and torque application. They also include specifications for head heights and Across Flats (AF) measurements, making them a go-to reference for both professionals and DIY enthusiasts. This data is crucial for safe and efficient installations in woodworking and construction projects.

Safety and Liability

Proper fastener selection is the user’s responsibility. Liability arises from application conditions beyond manufacturer control. Always refer to size charts and follow torque specifications to ensure safety.

10.1 Proper Fastener Selection Responsibility

Proper fastener selection is solely the responsibility of the user or specifier. Application conditions vary and are uncontrollable by manufacturers, making it crucial to adhere to size charts and technical data.

Liability for fastener performance lies with the user, as manufacturers cannot account for all variables. Always consult load capacity, torque specifications, and pilot hole requirements to ensure safe and reliable use.

Referencing the 2005 NDS code and understanding withdrawal capacity ensures compliance with structural standards, minimizing risks and potential failures in critical applications.

10.2 Application Conditions and Liability

Application conditions for lag bolts vary widely, and manufacturers cannot assume liability for their use. Users must ensure proper selection and installation based on specific project requirements.

Liability for fastener performance rests solely with the user, as manufacturers cannot control external factors like material quality or environmental conditions. Always adhere to provided specifications and guidelines to minimize risks.

Understanding withdrawal capacity and lateral design strength is crucial for safe applications. Proper torque and pilot hole sizing further ensure reliability and compliance with structural standards.

Installation Best Practices

Always pre-drill pilot holes to avoid splitting wood. Use correct torque specifications and ensure proper alignment. Tighten firmly with a wrench for secure connections.

11.1 Pre-Drilling Requirements

Pre-drilling is crucial to prevent wood splitting and ensure proper lag bolt seating. Hole diameter should match bolt shank size, typically slightly larger than the body diameter. For larger bolts, use a pilot bit to guide the screw accurately. Depth must accommodate the full thread length without over-drilling, ensuring maximum holding power. Always align the drill perpendicular to the wood surface to maintain structural integrity and avoid angled installations. Proper pre-drilling enhances safety and durability in all applications.

11.2 Torque Specifications

Torque specifications for lag bolts vary by size and material. Proper tightening ensures optimal grip without damaging threads. Use a torque wrench to avoid over-tightening, which can strip threads or weaken the bolt. For standard lag bolts, torque values range from 30-100 ft-lbs, depending on diameter and material. Always consult the manufacturer’s guidelines or the lag bolt size chart for precise torque recommendations. Over-tightening can compromise the structural integrity, while under-tightening may lead to loose connections. Adhere to specified torque limits for safety and reliability.

Selecting the right lag bolt size is crucial for ensuring structural integrity and safety in woodworking and construction projects. Proper sizing prevents over-tightening, thread stripping, and material damage. Always refer to lag bolt size charts for precise specifications, and consider factors like material type, load capacity, and torque requirements. Misuse can lead to structural failure or safety hazards. By following guidelines and using resources like torque specifications and pilot hole recommendations, you can achieve secure and durable connections. Understanding lag bolt sizing is key to successful project outcomes.